The cool days of early spring are behind us and the hot, hotter, hottest days of summer lie ahead. If your car's air conditioning is not pumping out the ice cold air like it used to, don't wait till it is so hot your sweating right through the seat. Have your A/C system checked and fight back the Florida heat and humidity. Keep reading for a brief overview of how your car's A/C system works, the components, and what Full Blown Automotive Center can do to keep you cool this summer!

In 1939 Packard became the first automobile manufacturer to offer air conditioning and heating as an option in their cars. These early systems were large, bulky, and inefficient. They were typically only installed in high-end luxury models and limosines as they required extensive plumbing to be ran throughout the body of the car and were prohibitively expensive to produce, install, and maintain. Other auto manufacturers attempted various cooling and heating systems, but automotive air conditioning remained too expensive and out of reach for the average consumer. In 1954 the Nash Motor Co. introduced the Nash Ambassador with, what we would consider, a modern air conditioning system. The Nash system managed to downsize the components of the A/C system allowing all the components to be fitted under the hood/cowling and was the first to have dash mounted controls. It was also the first system offered by any manufacturer to incorporate both heating and cooling in one complete package rather than as seperate, more complex and expensive sytems. The Nash "Weather Eye" system became the standard of automotive heating and cooling, and is the basis of modern systems today.

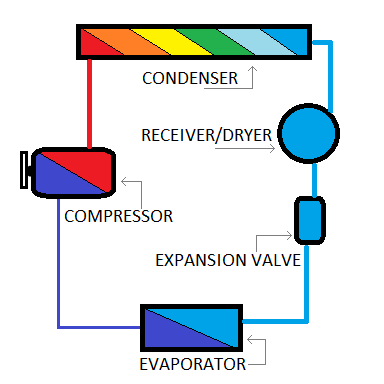

Modern automotive A/C systems operate on simple principles of physics and thermodynamics, but don't worry, we won't throw all the math at you. Basically, the system operates by changing pressure of a chemical refrigerant to change temperature from hot to cold, as well as removing moisture and contaminants, and eventually blowing the cold air into the vehicle cabin. The A/C system does not create cold air, rather it removes heat from the air leaving cold air in it's place. The process repeats continually assuming there are no problems in the system or it's components.

Refrigerant

The refrigerant is the lifeblood of the A/C system. Not unlike motor oil, brake fluid, or engine coolant; the refrigerant is specifically designed to work in your A/C system. Traditionally, automotive A/C refrigerant is known as "Freon" referring to an early generic refrigerant developed by DuPont. Modern auto A/C will use either R-12/R-22(1987 and older), or R-134a(1988-2013), or HFO-1234yf(2013 and newer) refrigerant. Older vehicles are likely to use R-12 or R-22 and may require a retrofit in order to be serviced with R-134a or HFO-1234yf. Certain vehicles may be able to be recharged with a special refrigerant mixture (R-407c) designed to bridge older systems with modern enviromental standards. It is important to ensure the right refrigerant is used in your system as it will be repeatedly converted from liquid to gas and back to liquid as it cycles the system's components which are optimized for use with a specific refrigerant. The most common problem with your car's A/C system is likely to be refrigerant, and your system needs to be inspected for leaks with dyes or specialized "sniffer" equipment and recharged. There are recharge kits available at auto parts store, however, these kits can be difficult to use and without proper inspection of the system could result in spending more money and could even result in damage to system components. It is stongly recommended that you have your system inspected and recharged by a certified technician.

Compressor

If refrigerant is the lifeblood of the system, then the compressor is the heart of the system. The compressor compresses or squeezes the refrigerant gas to increase pressure and thus increase refrigerant temperature. The compressor is contolled by an electric clutch that engages and disengages depending on outside air temp or by the settings made on the dash mounted A/C controls. The compressor is powered via pulley and serpentine belt connected to the engine. If the A/C is not working at all, working erratically, or is making lots of noise could be indicators that the compressor or compressor clutch have gone bad. Some vehicles may have a seperate belt just for the compressor that may need replacement. Refrigerant leaks could also occur at the compressor.

Condenser

The next component in the system is the condenser coil. The condenser coil is located at the front of the vehicle, and usually looks like a miniature radiator. Cool air is pushed (either by vehicle movement or powered fan) through the condenser. As cool air passes through the coils heat is exchanged from the condenser to the air causing the refrigerant temperature to drop and turning back into a liquid state. Issues with the condenser are usually leaks arrising from corrosion or impact from debris damaging the coils.

Receiver/Dryer or Accumulator

After being condensed the refrigerant will pass through a receiver/dryer or accumulator depending on the type of A/C system equipped on the vehicle. The receiver/dryer seperates any remaining gas from the liquid refrigerant, removes moisture by way of a dessicant (similar to those small packets found in packaging of new products), and filters out contaminants which may be trapped in the system. The accumulator has a similar function. A problem with either component can be identified by moisture on the window and inability of the defroster to remove the moisture from the window. It is important to note that anytime the system is opened for service the receiver/dryer or accumulator will need replacement.

Expansion Valve or Orfice Tube

The next component of the A/C system again depends on what type of sytem is equipped on the vehice. It is either an expansion valve or orfice tube, both of which have a similar function. They monitor and control the amount of refrigerant that is allowed to enter the evaporator. Poor A/C performance could indicate a problem with these components. It is important that these components are functioning correctly as failure could lead to evaporator damage.

Evaporator

The final component of the A/C closed refrigerant system is the evaporator. The evaporator is usually located behind the passenger side dash. The evaporator also removes moisture, but the primary function is to cool air by exchanging heat as low pressure, low temperature refrigerant is passed though the evaporator coil. The refrigerant then repeats it's cycle passing back to the compressor. The cool air passed through the evaporator coil is then passed through the cabin ventilation ducts via a blower motor to control the force of air coming from the ducts. Again, poor A/C performance could indicate a problem with the evaporator.

Automotive A/C systems may not have changed much since the 1950's, however they are a complex systems that could have leaks or component failures in one or multiple places in the system. At Full Blown Automotive Center we have the expertise, tools, and equipment to ensure your A/C is blasting ice cold air. Whether you just need a recharge, a retrofit, or component replacement we have everything you need. Don't let the Florida heat get you beat! Stop by Full Blown Automotive Center to have our technicians inspect and repair your system properly today!